FITWELL ENGINEERING COMPANY

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to FITWELL ENGINEERING COMPANY

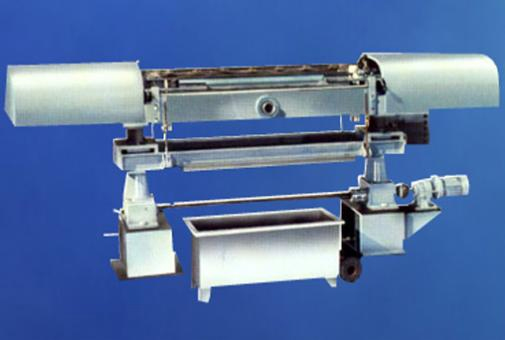

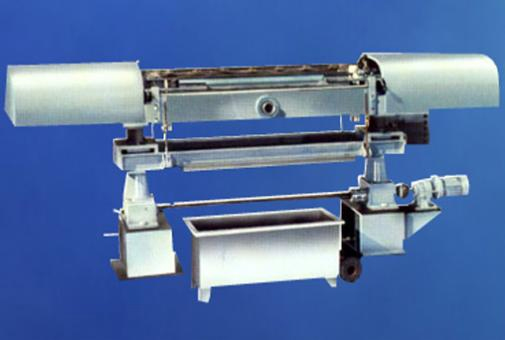

Coating Machine For Board And Paper On Line And Off Line

Bar Coater is well designed for precise and uniform coating on Paper & BoardCoating Solution is applied to a running web by an applicator Roll and then metered by a smooth ground finish metering bar. Coat weight is achieved by increasing diameter of metering bar & the linear speed of applicator roll. For even tension of paperboard on Metering Bar is given by Evener Roll. All rolls are ground finish and Hard Chrome coated.This Coating Machine is very simple in running and there is nothing to wear except Metering Bar and Bar Bed. Control Panel with VFD Control to Control Linear speed of Applicator Roll & Metering Bar is supplied with Coating Machine

Hot Air Drying System

Bar Coater is well designed for precise and uniform coating on Paper & BoardCoating Solution is applied to a running web by an applicator Roll and then metered by a smooth ground finish metering bar. Coat weight is achieved by increasing diameter of metering bar & the linear speed of applicator roll. For even tension of paperboard on Metering Bar is given by Evener Roll. All rolls are ground finish and Hard Chrome coated.This Coating Machine is very simple in running and there is nothing to wear except Metering Bar and Bar Bed. Control Panel with VFD Control to Control Linear speed of Applicator Roll & Metering Bar is supplied with Coating Machine.

Brush Calendar

After coating on board surface, brushing is required for getting GLOSS on board surface. We manufacture Brush Calendar having Two Brush Rolls for brushing top side of board and one brush roll for back side of board. Brush Roll run's on two antifriction bearing and roll remains rigid in one position. For loading board against brush rolls, paper lead rolls are used and loading & unloading of paper lead rolls is done by pneumatic cylinders. There are adjusting screws with each pneumatic cylinder. We can level paper lead rolls as per board and adjust load on board with help of adjusting screws. These adjusting screws also guide bearing housings of paper lead roll.As complete machine is horizontal design, so paper feeding is very easy without any help of paper feeding rope carrier system. The machine is maintenance free and runs very smooth without vibrations. As machine is vibration free, so there are no patch types marking on paper surface. Overall machine is complete in all respect.

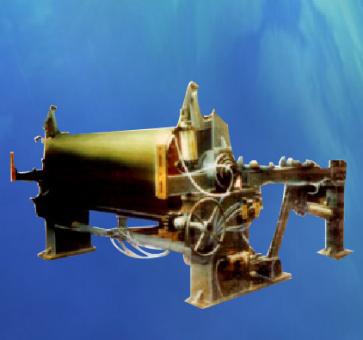

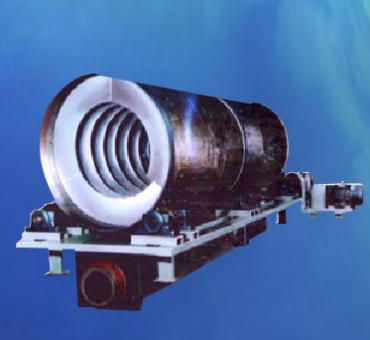

Thickener

Description / Specification of Thickener

We are involved in offering a wide range of Thickener to our most valued clients. Our range of these are widely appreciated by our clients which are situated all round the nation. We offer our range of it at most affordable prices.

We introduce ourselves as an eminent trader and supplier of an extensive array of Thickener. Prior to dispatch, our quality controllers run numerous tests on the entire range on various parameters of quality and durability. The offered equipment is manufactured using superior quality components with the aid of sophisticated techniques at the vendors' end. Moreover, our precious clients can purchase it in different technical specifications at reasonable price from us within promised time frame.

Features:

Sturdy design

Highly durable

Application specific design

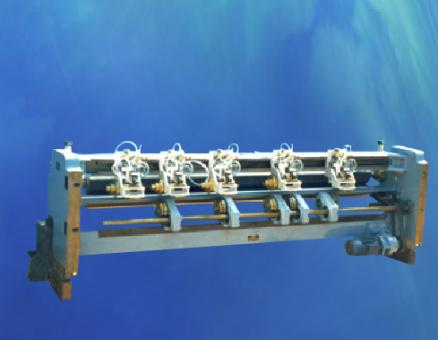

Cutter Slitting Station

Bottom Circular knife is fix and rotates with shaft with sliding arrangement to adjust at any position. It has arrangement to change bottom circular knife individually. Top Circular knife has pneumatic arrangement to lower the knife and adjust pressure with bottom circular knife for better slitting finish and more knife life. Two slitting station can be fitted on one on line sheet cutter for changing size quickly.

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.